Hydrogen Uses

Hydrogen is a uniquely versatile energy carrier. It can be produced using different energy inputs and different production technologies. It can also be converted to different forms and distributed through different routes – from compressed gas hydrogen in pipelines through liquid hydrogen on ships, trains or trucks, to synthesized fuel routes.

Hydrogen is a key solution to cut greenhouse gas emissions in sectors that are hard to decarbonise and where electrification is difficult or impossible. This is the case of industrial sectors such as steel production, or heavy-duty transport for example. As a carbon-free energy carrier, hydrogen would also allow for transport of renewable energy over long distances and for storage of large energy volumes.

An immediate application in industry is to reduce and replace the use of carbon-intensive hydrogen in refineries, the production of ammonia, and for new forms of methanol production, or to partially replace fossil fuels in steel making. Hydrogen holds the potential to form the basis for zero-carbon steel making processes in the EU, envisioned under the Commission's New Industrial Strategy.

In transport, hydrogen is also a promising option where electrification is more difficult. For example in local city buses, commercial fleets or specific parts of the rail network. Heavy-duty vehicles including coaches, special purpose vehicles, and long-haul road freight could also be decarbonised by using hydrogen as a fuel. Hydrogen fuel-cell trains could be extended and hydrogen could be used as a fuel for maritime transport on inland waterways and short-sea shipping.

In the long term, hydrogen can also become an option to decarbonise the aviation and maritime sector, through the production of liquid synthetic kerosene or other synthetic fuels.

Of course, hydrogen can also be used across a range of different applications – including the 36 end use applications described in the Hydrogen Council´s “Path to Hydrogen Competitiveness” study.

Primary uses of hydrogen today are as a chemical feedstock in ammonia, food, and drug production, as well as petrochemical and refinery processing. It is also used in crystal growth, glass manufacturing, chemical tracing, metal fabrication, polysilicon and semiconductor manufacturing, metal production, and thermal processing.

Oil refinery hydrogen demand is a major component of the overall hydrogen production. Hydrogen is used to remove sulfur and to hydrotreat and hydrocrack heavier crude oil constituents into more valuable, lighter products. In turn, growth in refinery hydrogen demand is affected by an increase in demand for liquid fuels, changes in sulfur content of the raw crude oil, and regulations that limit the amount of sulfur in the liquid fuel. Fertilizer and chemical production also consume large quantities of hydrogen. The U.S. ammonia supply is dependent on the price of natural gas and the supply has increased because of the low price of natural gas. Both brownfield capacity expansions and greenfield ammonia plants are coming online, leading to increased demand for hydrogen.

Other potential hydrogen utilization areas include the following:

• Industrial Uses: Hydrogen can replace coke and natural gas as a reducing agent in iron and steel production.

Similarly, hydrogen can enable decarbonization of industries, such as cement, fertilizer, and petrochemicals.

However, in some cases, considerable R&D may be required to assess the effects of switching from natural gas or coal-derived fuel gases to pure hydrogen.

• Transportation: Hydrogen-powered fuel cell vehicles offer both high efficiency and low emissions. They can play an increasingly important role in reducing emissions from long-haul trucks, heavy-duty trucks, buses, medium and large cars, vans, minibuses, trains, ships, and planes.

• Power Generation: Hydrogen use for power generation is negligible today, though there is potential for its role in power production. Hydrogen can be injected into existing natural gas pipeline networks or directly sent into the end-distribution network. Hydrogen-fired gas turbines and combined-cycle gas turbines could also be a source of flexibility in electricity systems. In addition, Solid Oxide Fuel Cells (SOFCs) can offer the highest conversion efficiency of chemical-energy-to-electrical-energy of any energy conversion technology, compared to any heat engine.

• Energy Storage/Grid Balancing: Hydrogen could become a long-term storage option to balance seasonal variations in electricity demand. Industry has been working on technologies to store hydrogen in cryogenic vessels or in high-capacity sorbents to increase the energy density and duration available. Geologic storage of hydrogen is feasible in salt caverns and other formations. A limited number of geologic storage projects exist in the United States, which could expand as the demand for hydrogen increases.

Sector coupling strategies by increasing the use of renewable power in other sectors

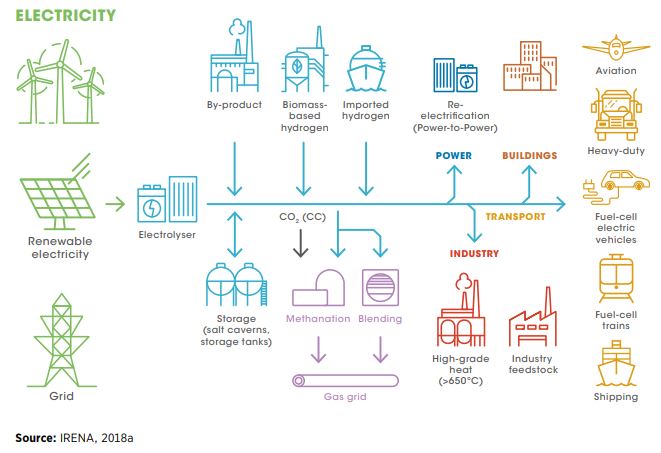

Hydrogen can be used to couple renewable electricity with other energy use sectors as depicted in Figure. Some of the applications of hydrogen are listed below.

As Figure illustrates, hydrogen contributes to “sector coupling” – on the one hand between the power system and on the other between the industrial, buildings and transport sectors.

Sector coupling creates extra loads that represent new markets for hydrogen produced from VRE sources, furthering the integration of high shares of VRE in the power system.

Well-defined safety standards, appropriate ventilation and leak detection are required to ensure safe operations with hydrogen. It is a highly flammable gas and can burn at a wide range of concentrations.

The US National Fire Protection Association gives hydrogen a 4, the highest flammability rating, denoting materials “that completely vaporise at normal pressure and temperature and burn readily”.

These standards already exist for various industrial applications, but they may need to be streamlined considering emerging new applications of hydrogen, for example as a fuel for cars.

Some of the applications are listed below:

As feedstock:

Hydrogen can be used as feedstock in the chemical industry. It is a key input to the production of ammonia, synthetic fuels and various types of fertiliser. It can also be used in the methanation process to produce methane from CO₂. Hydrogen is also used to produce synthetic liquid fuels from biomass, which increases the efficiency of biomass utilisation significantly. Hydrogen can also be used to replace fossil fuels and act as a reducing agent in heavy industries such as steel. In Sweden, for instance, the HYBRIT project aims to replace coking coal with hydrogen in the ore-based steelmaking process.

As fuel:

Hydrogen can provide power using fuel cells. For example, Europe hosts 95 hydrogen stations where a fuel cell can be refuelled in three minutes for a range of 500–800 kilometres (H₂ live, 2019). Another way to use hydrogen as a fuel is to blend it with natural gas in the existing natural gas pipelines.

Standards suggest blending up to 10% hydrogen (by volume), with a potential to increase it to 20% (Hydrogen Strategy Group, 2018) (NREL, 2015) (IRENA, 2018a). However, the appropriate blend may vary significantly between pipeline network systems and natural gas compositions and must therefore be assessed on a case-by case basis (NREL, 2013; ARENA, 2018). The current limit on hydrogen in gas turbines and engines should be increased in the near feature.