Hydrogen Transportation & Delivery

Hydrogen transportation, distribution, and storage are the primary challenges for integrating hydrogen into the overall energy economy system. On a mass basis, hydrogen has nearly three times the energy content of gasoline. While hydrogen has high energy density per unit mass, it has low-volumetric energy density at room conditions (around 30% of methane at 15 °C, 1 bar) and an ability to permeate metal-based materials, which can present operational and safety constraints. This makes transporting hydrogen a challenge because it requires high pressures, low temperatures, or chemical processes to be stored compactly.

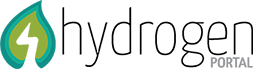

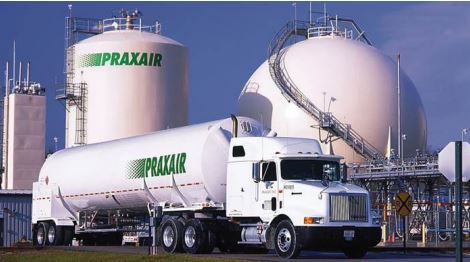

Gaseous hydrogen is usually transported by either tube trailers or pipelines, while liquid hydrogen is moved by road tankers. Liquid hydrogen shipping is also being considered as a means for transporting large volumes between countries.

Depending on transportation distance and volumes, trucking may be preferred for short distances and small volumes, while liquid tankers or pipelines are more economical for long distance, larger volume transport. Figure illustrates the primary means of hydrogen transportation.

Pipelines:

Existing domestic natural gas pipeline infrastructure has the potential to expand the transportation of hydrogen.c Blending hydrogen into natural gas pipeline networks may be an option for delivering pure hydrogen to markets, using separation and purification technologies downstream to extract hydrogen from the natural gas blend near the point of end use. It is necessary to assess multiple factors to safely integrate hydrogen blending into the existing natural gas pipeline systems (e.g., gaseous hydrogen embrittlement).d Notionally, pipelines can handle from 15%–30% hydrogen blends without modifications or significant detrimental effects.e While hydrogen compression can be utilized for transport and storage, this compression comes with energy penalties up to 20% of the energy content required for compression.

Trucking:

Hydrogen that is transported via truck is typically hauled in either liquid tanker trailers or tube trailers. High-pressure cylinders and tube trailers at ~2,600 pound-force per square inch (psi) are commonly used to distribute gaseous hydrogen within 200 miles of the source. Hydrogen transport by truck typically involves high-pressure tube trailers that operate at pressures twice the amount of normal transporting pressures. Liquid tanker trailers are used for transport distances up to 600 miles. Cryogenic liquid hydrogen trailers operate at near atmospheric pressure.

Other:

Compared to trucks, it could be more economical to transport hydrogen by railcars, barges, or ships for larger quantities of hydrogen. By utilizing the same style of tube or liquid tanks used by trucks, these modes of transport are not restricted by weight requirements encountered on roadways. The first liquid hydrogen transport ship was launched as a pilot in Japan at the end of 2019, with an anticipated storage capacity of 1,250 m3 (less than 1% of typical LNG carriers). It is expected that the next version will have greater capacityThe increased number of retail hydrogen fueling locations in select markets is supporting the initial rollout of fuel cell electric vehicles (FCEVs). Manufacturers including Honda, Hyundai, and Toyota are currently offering production FCEVs for sale or lease to customers in markets where hydrogen fuel is available, primarily in California. With careful planning, the focus has been to add hydrogen fuel at existing gasoline stations covering regions in northern California near San Francisco and southern California near Los Angeles and San Diego, with additional connector and destination stations.

Hydrogen Storage

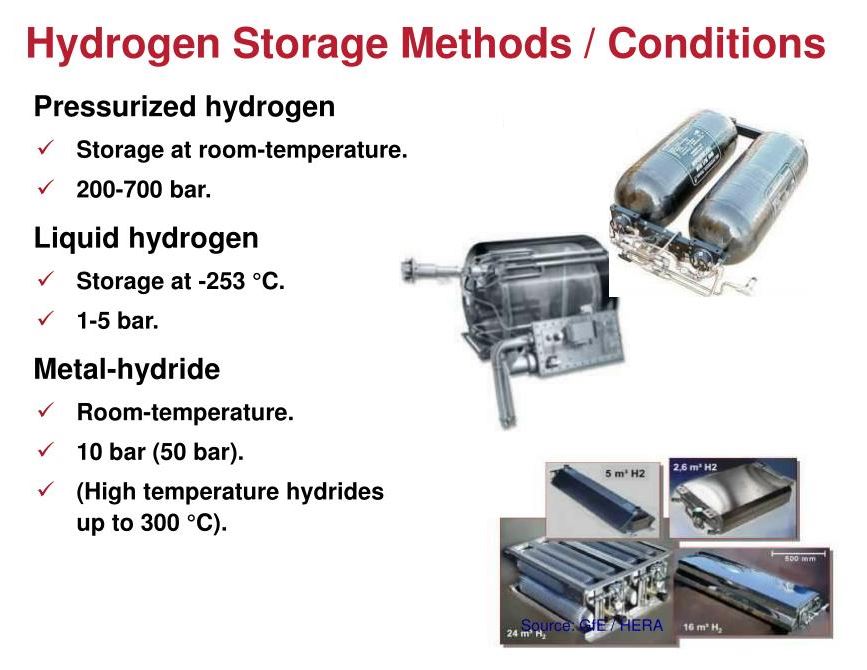

Today, hydrogen is most commonly stored as a gas or liquid in tanks for small-scale mobile and stationary applications.

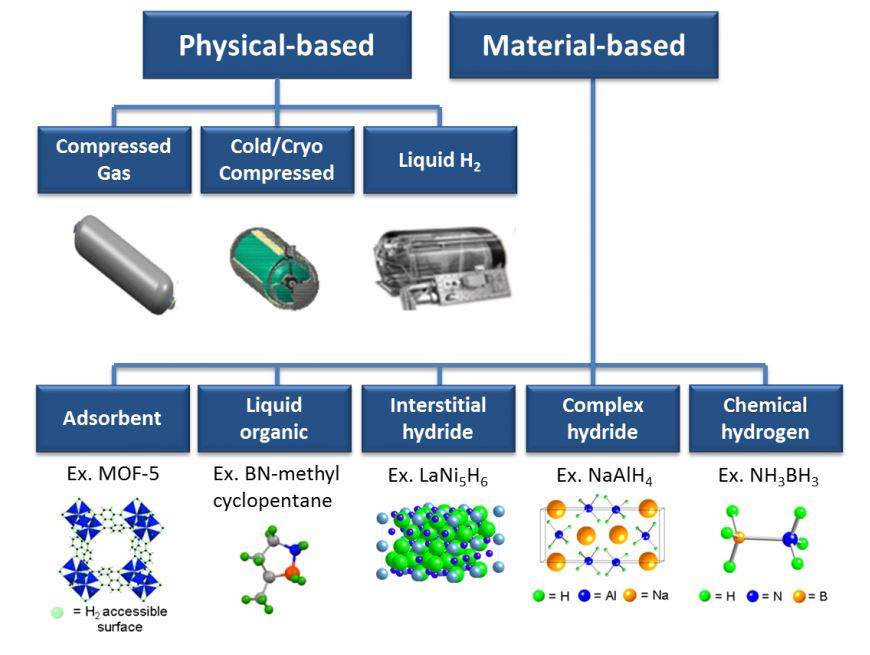

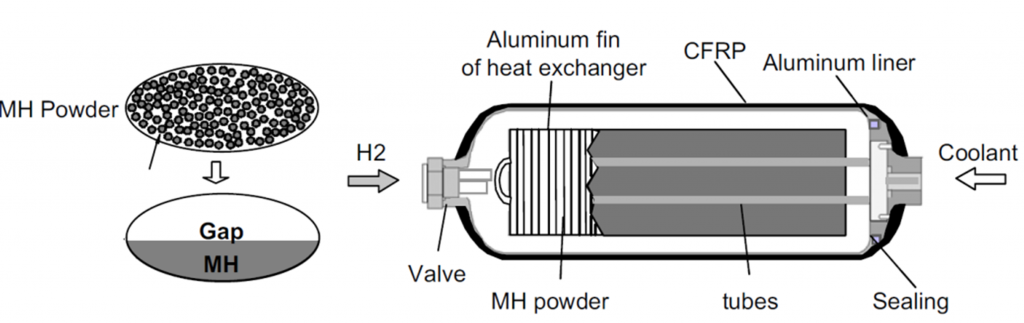

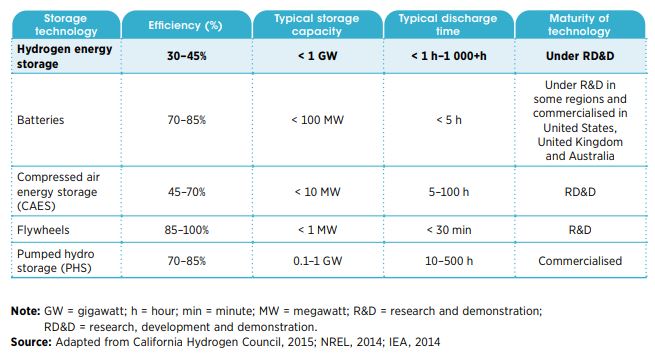

Hydrogen storage options include compression or cryogenic systems (or their combination), chemical production systems (such as ammonia), nanomaterial-based storage, and geologic storage. Compression and cooling systems are required for transportation and storage of hydrogen. A variety of metal tanks are typically found at production facilities, transport terminals, and end-use locations. While cryogenic systems are the most common way to store large amounts of hydrogen, advancements in porous nanomaterials may provide another storage mechanism. Within these structures, hydrogen can be stored in non-reactive media, at low-temperature, and with quickly reversible adsorption/desorption of hydrogen without requiring thermal energy. Storing hydrogen as ammonia, conversely, requires thermal energy to decompose the molecules when the hydrogen is needed. Hydrogen storage is a key technological barrier to the development and widespread use of fuel cell technologies in transportation, stationary, and portable applications.

To address the needs for advanced energy storage technologies DOE/RTIC launched in the year 2020 a gross cutting effort to accelerate the energy storage technologies toward hydrogen integration into a large scale energy system called H2 & scale vision of HFTO.

The hydrogen storage, where element hydrogen is stored, or materials based storage where hydrogen is bound with other materials

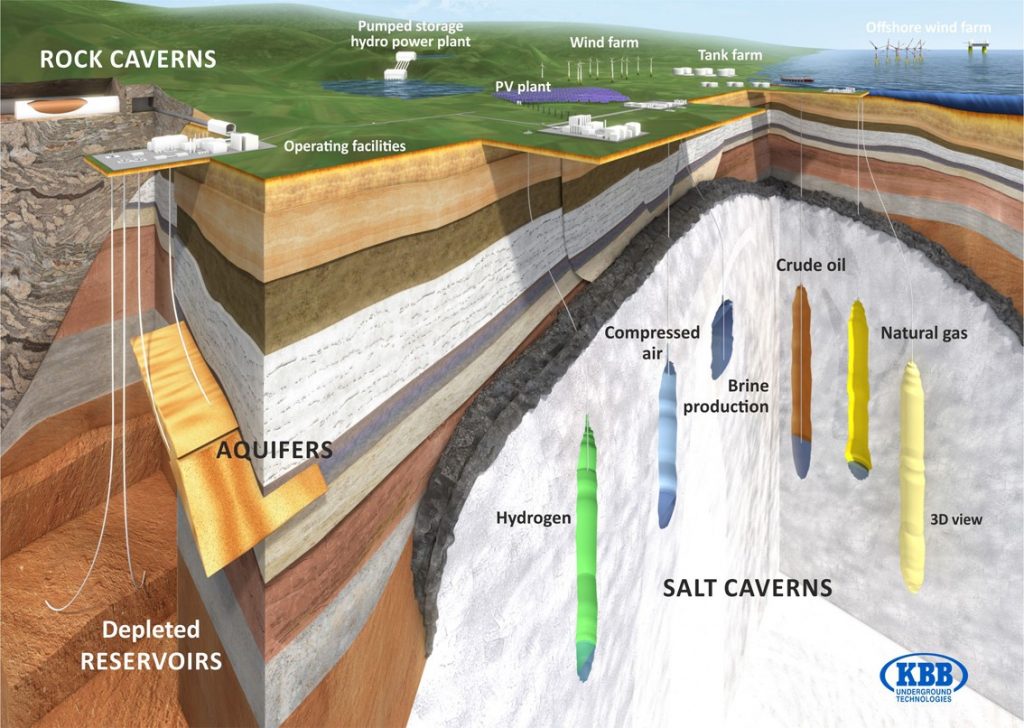

Large-scale hydrogen value chains in the future will require a much broader variety of storage options. In general, geological storage in many regions of the country is the best option for large-scale and long-term storage, while tanks

are more suitable for short-term and small-scale storage. Geologic storage within salt caverns, saline aquifers, depleted natural gas or oil reservoirs, and engineered hard rock reservoirs can also be used as long-term storage mechanisms.

Hydrogen can also be stored in large quantities underground, in caverns, salt domes and depleted oil and gas fields. The image below demonstrates the potential for the storage of large quantities of hydrogen in salt caverns. There are many storage sites across the globe such as the ICI salt cavern in Teesside, England storing 95% pure hydrogen and 3 – 4% CO2.

Further work is required to characterize this opportunity and validate these formations through R&D, geologic characterization, and validation of reservoirs. Storage efforts will be coordinated with EERE which has led the National Storage Project and has substantial ongoing activities

To see more : https://acadbuddy.com/hydrogen-storage/