Sources of Renewable Energy

Solar Power

Solar energy is a large, inexhaustible source of energy.

The power from the sun intercepted by the earth is approximately 1.8 × 1011 MW which is several thousand times greater than the present consumption rate of all commercial sources of energy on the planet.

Solar energy could in theory supply continuously all the energy needs of the world today and the future, making it one of the most promising sources of renewable energy.

The energy from the sun is used in two ways directly.

The first is the thermal route by which the heat energy from the sun is collected by means of devices. This thermal energy is either used immediately for applications such as water heating, space heating, drying, etc. or transformed by means of energy transfer cycles into electricity.

The second way to directly use solar energy is by photovoltaic conversion, the devices used for this purpose is called solar cells.

Wind Power

Wind power or wind energy is the use of wind to provide mechanical power through wind turbines to turn electric generators for electrical power. Wind power is a popular sustainable, renewable energy source that has a much smaller impact on the environment compared to burning fossil fuels.

Wind farms consist of many individual wind turbines, which are connected to the electric power transmission network. Onshore wind is an inexpensive source of electric power, competitive with, or in many places cheaper than, coal or gas plants. Onshore wind farms have a greater visual impact on the landscape than other power stations, as they need to be spread over more land and need to be built in rural areas, which can lead to "industrialization of the countryside" and habitat loss. Offshore wind is steadier and stronger than on land and offshore farms have less visual impact, but construction and maintenance costs are significantly higher. Small onshore wind farms can feed some energy into the grid or provide power to isolated off-grid locations.

Marine renewable energy

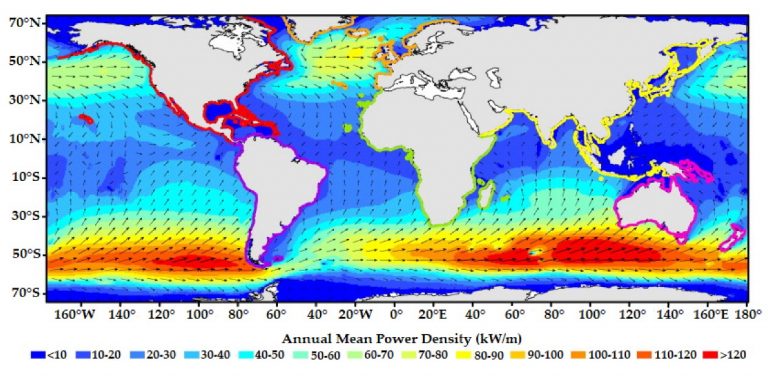

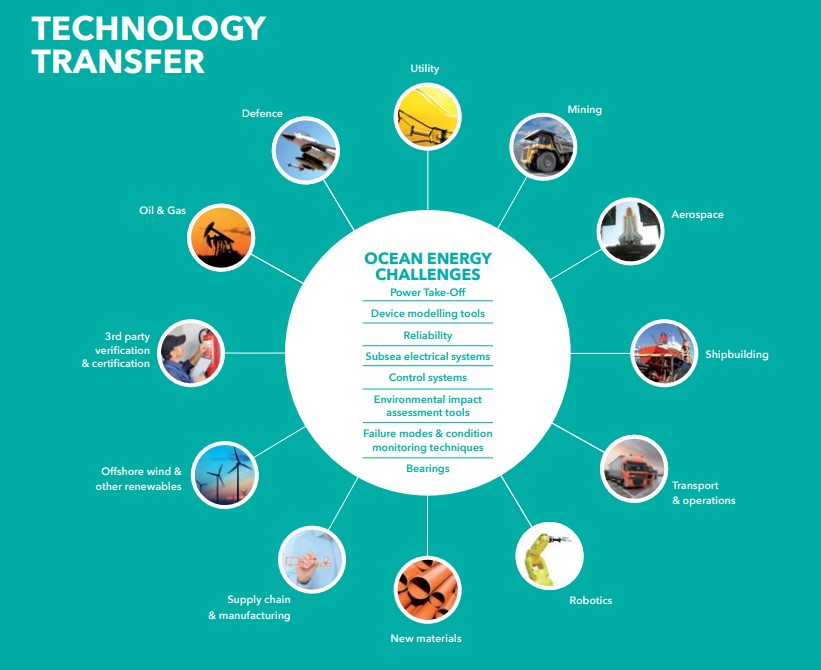

The movement of water in the world’s oceans creates a vast store of kinetic energy. Marine Renewable Energy (MRE), also known as Marine Hydrokinetics (MHK), can be harnessed to generate electricity to power homes, transport and industries. MRE encompasses wave power — power from the movement of surface waves, tidal power — power from the kinetic energy of large bodies of moving water, ocean current power — power from the kinetic energy of ocean current, and ocean thermal energy conversion (OTEC) — power from the heat differential of different thermal layers within a body of water.

Wave Energy

Ocean surface waves are generated by wind passing over the ocean surface. The friction between the wind and ocean surface causes energy to be transferred from the faster moving air to the surface layer of the ocean. Wave development depends on the length of ocean, or “fetch,” over which the wind blows in a constant direction. Longer fetches with higher wind velocities will produce larger waves. Waves can travel thousands of miles with little energy loss and can combine with waves from storms and other wind-driven events to create very energetic seas. The energy of ocean waves is concentrated at the surface and decays rapidly with depth.

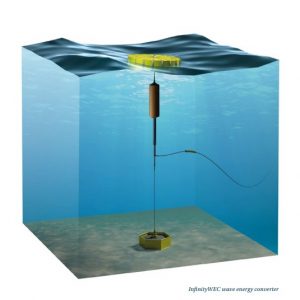

Wave energy converters (WECs) capture the energy contained in ocean waves to generate electricity. Extracting energy from ocean waves is not a recent phenomenon, as researchers have been studying different concepts or solutions since the 1970s. Nowadays, the technology has evolved to a phase where different concepts are being tested at a full scale, pre-demonstration phase, and commercial demonstrations are being deployed. In 2013, there were more than a hundred projects at various stages of development, as estimated by some recent reviews (Falcao, 2010; Bahaj, 2011).

There is a wide range of wave energy technologies. Each technology uses different solutions to absorb energy from waves, and can be applied depending on the water depth and on the location (shoreline, near shore, off shore) (Cruz, 2008; Falcao, 2010). Although there is a wide range in technologies that signals that the sector has not yet reached convergence, it also shows the many different alternatives to harness wave power under different conditions and emplacements.

Future evolution of the sector will aim for an initial deployment of demonstrating WECs in small arrays of 10 MW, close to shore or on specific testing emplacements. Making the jump to the full commercial phase requires some research on the basic components to reduce costs and increase the performance. Also other solutions, such as hybrid or multiplatform concepts, could represent a solution that accelerates wave technology development. These platforms would combine wave energy technologies with offshore wind turbines or with aquaculture farms, which would result in a sharing of the foundation system costs, lower operation and management costs, and some environmental benefits as the impact of a combined emplacement will be smaller than that with different locations.

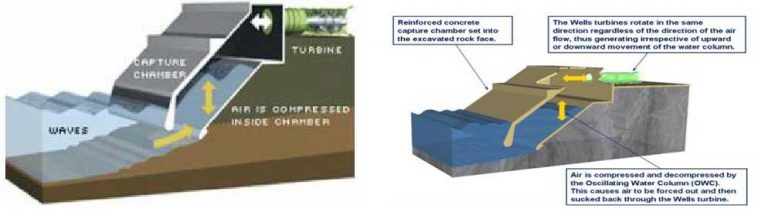

Wave energy technologies consist of a number of components: 1) the structure and prime mover that captures the energy of the wave, 2) foundation or mooring keeping the structure and prime mover in place, 3) the power take-off (PTO) system by which mechanical energy is converted into electrical energy, and 4) the control systems to safeguard and optimise performance in operating conditions There are different ways in which wave energy technologies can be categorised, e.g., the wave energy is converted into mechanical energy.

One way to categorise wave energy technologies is by how the device extracts the surge, heave or sway motions of the wave (or a combination of each) (EMEC, 2014). In general, point absorbers convert the “heave” to drive a piston up and down, terminators and oscillating wave surge converters convert the “surge”, and attenuators convert the “pitch” of the wave to drive a rotor. Over half (53%) of WEC concepts developed are point absorbers, 33% terminators, and 14% attenuators (IRENA, 2014).

Tidal power

Current energy can be captured from tidal channels, ocean currents, or rivers. Ocean current energy technologies capture the energy from the relatively constant flow of ocean currents, which are driven by several factors, including wind, bathymetry, and the rotation of the Earth, as well as water temperature, density, and salinity. Tidal energy technologies capture the energy from flow induced by the rise and fall of tides, which is driven by gravitational influence of the moon and sun on the earth’s oceans. Land or subsea constrictions, such as straits and inlets, can create high velocity currents at specific sites, making them suitable for electricity generation. Riverine energy technologies extract the kinetic energy from flowing water in rivers to generate electricity. Although not technically a marine resource, as part of the natural hydrological cycle, precipitation from drainage basins, groundwater springs, and snow melt feed rivers that flow towards lakes, seas, and oceans.

Ocean Thermal Energy Conversion

Ocean thermal energy conversion (OTEC) technology converts solar energy stored in the layers of the tropical and subtropical oceans. Thermal heat engines use the temperature difference between the sun-warmed surface water and cold water in the deep ocean.

Salinity gradient

Salinity gradient technologies generate electricity from the chemical pressure differential created by differences in ionic concentration between freshwater and saltwater. Seawater has a higher osmotic pressure than freshwater due to its high concentration of salt. Two main technology types, Reverse Electro Dialysis (RED) and Pressure Retarded Osmosis (PRO), make use of semi-permeable membranes which generate an osmotic potential that can be used to generate electricity using turbines in deltas or fjords.

Geothermal energy

Geothermal energy is energy coming from the Earth’s inner molten crust towards the surface.

Since the Earth’s crusts have no homogeneity, several local hot spots are situated just under the surface where the temperature is substantially higher than the expected average value.

For some of these areas, groundwater comes into contact with hot rocks, and as a result, dry steam, wet steam, and hot water or hot water alone are formed.

A well drilled to these locations causes the steam or water to emerge at the surface where its energy can be utilized either for generating electricity or for space heating.

Microbial Biomass

Microbial biomass conversion processes take advantage of the ability of microorganisms to consume and digest biomass and release hydrogen. Depending on the pathway, this research could result in commercial-scale systems in the mid- to long-term timeframe.

In fermentation-based systems, microorganisms, such as bacteria, break down organic matter to produce hydrogen. The organic matter can be refined sugars, raw biomass sources such as corn stover, and even wastewater. Because no light is required, these methods are sometimes called "dark fermentation" methods.

In direct hydrogen fermentation, the microbes produce the hydrogen themselves. These microbes can break down complex molecules through many different pathways, and the byproducts of some of the pathways can be combined by enzymes to produce hydrogen. Researchers are studying how to make fermentation systems produce hydrogen faster (improving the rate) and produce more hydrogen from the same amount of organic matter (increasing the yield).

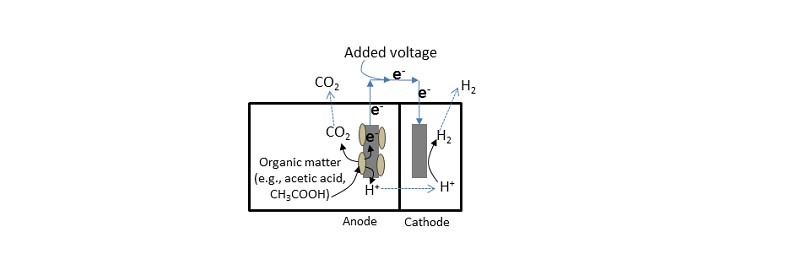

Microbial electrolysis cells (MECs) are devices that harness the energy and protons produced by microbes breaking down organic matter, combined with an additional small electric current, to produce hydrogen. This technology is very new, and researchers are working on improving many aspects of the system, from finding lower-cost materials to identifying the most effective type of microbes to use.

Biomass is an abundant domestic resource, and many microbes have evolved to efficiently break down biomass to produce hydrogen and other products. Fermentation has already been used as an industrial technology to generate biofuels and other products, and many of the challenges to scaling up systems have been addressed for different products, allowing hydrogen researchers to focus on the challenges unique to hydrogen production. MEC-based systems have the potential to produce hydrogen from resources that otherwise can’t be used for fuel production, and could reduce the large amount of energy normally needed for wastewater treatment while producing a valuable fuel in the form of hydrogen. These two pathways can be combined to maximize the hydrogen yield from the starting biomass feedstock.

Research in microbial biomass conversion for hydrogen production has progressed in recent years, but U.S. Department of Energy efforts are working to address a number of challenges. Key areas of research and development include:

Improving the rates and yields of hydrogen production from fermentation processes through a number of methods such as microbial strain improvements, reactor system optimization, and identifying feedstock sources and processing methods with the highest yields.

Developing MEC systems that can be scaled up to commercially relevant sizes while maintaining the production rates and system efficiencies seen at the bench scale and minimizing the costs of the reactor components.

There is untapped potential in the large amounts of food waste produced by modern society. Researchers have developed a process that efficiently ferments biological waste to extract hydrogen (H2) gas.

More than 130 million tonnes of biological waste is produced every year in the EU, from gardens, kitchens, restaurants and the food processing industry. This waste constitutes an enormous untapped source of energy and other resources, provided it can be efficiently processed.

The EU-funded HYTIME (Low temperature hydrogen production from second generation biomass) initiative aimed to develop a bioprocess for the production of H2 gas from biological waste streams.

The researchers analysed various sources of waste, including grass cuttings, straw, and fruit and vegetables discarded by supermarkets. They also tested the effect of various pre-treatments using steam, diluted chemicals and enzymes on the final hydrogen yield.

RENEWABLE POWER TO HYDROGEN

Hydrogen is an energy carrier and can be produced from a wide variety of sources. Its market is well established, with global demand currently standing at around 8–10 exajoules (EJ), most of which is consumed in the chemical sector. At present, roughly 95% of worldwide hydrogen production comes from fossil fuels.

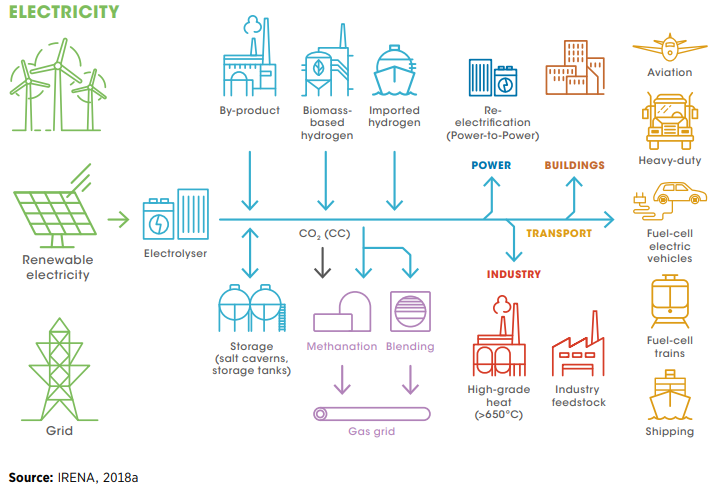

Hydrogen from renewables can be produced through various pathways, with the most established being the use of renewable electricity to split water into hydrogen and oxygen in an electrolyser. IRENA's report, Hydrogen from renewable power: Technology outlook for the energy transition, gives an overview of electrolyser technologies and highlights the technical potential to channel large amounts of renewable electricity to sectors for which decarbonisation is otherwise difficult – such as industry, buildings and transport, as well as in niche applications such as remote locations. By doing so, hydrogen from renewable power can directly displace hydrogen produced from fossil fuels, whilst also replacing fossil fuels as feedstocks in several processes.

A renewable energy perspective – released in 2019 at the second Hydrogen Energy Ministerial Meeting in Japan – expands on the previous report, providing insights on the steps required to develop hydrogen from renewables as well as related production cost forecasts.

IRENA’s work on hydrogen from renewable power focuses on assessing its role in the energy transition as an enabler for the integration of higher shares of renewable energy in the power sector and in end-uses such as transportation and manufacturing. Under this context, the IRENA FlexTool is used to assess the impact of hydrogen production on power systems and its potential to improve their flexibility.

During the tenth session of the IRENA Assembly in January 2020, the Agency organised the Ministerial Roundtable on Green Hydrogen. At the event, Member Countries and private sector stakeholders debated the potential of hydrogen from renewable power to decarbonise the global energy system and its relevance in different national energy contexts. Members shared insights on how they envisioned their roles in developing a global hydrogen supply chain. Participants included high-level representatives from Austria, Germany, India, Italy, Japan, Morocco, Saudi Arabia, the United Arab Emirates and the USA, as well as the European Commission, the International Partnership for Hydrogen and Fuel Cells in the Economy, the International Energy Agency and the Global Maritime Forum.

Renewable power to hydrogen P2H₂ can provide grid balancing services and long-term storage to manage the variation in power supply from wind and solar photovoltaic (PV) technologies. P2H₂ can also enable the use of clean hydrogen, produced from renewable energy sources, as feedstock in industrial processes and thereby help decarbonise other sectors.

To see more : hydrogen produced from renewable energy by IREA

An important distinction between hydrogen and other forms of energy storage is that hydrogen can be stored and transported through the existing natural gas network. Little investment is needed to adapt natural gas infrastructure to transport hydrogen. Blending hydrogen with other gases means that pure hydrogen is no longer available for direct use in different applications, e.g. fuel cell vehicles. Extracting pure hydrogen from blended gas is possible, but it is expensive and complicated, so there is an economic trade off to be made between the various hydrogen applications.

Electrolysis – Flexibility services when needed

Producing hydrogen from renewable power, especially when there is excess renewable electricity generation in the system, helps avoid curtailment and thereby improves the return on investment for VRE asset owners.

Electrolysis can also enhance the reliability of power supply by providing flexibility services when needed. With increasing penetration of VRE resources such as solar PV and wind, large-scale storage solutions and grid stability management are becoming critical issues in system operation.

Electrolysers can help integrate VRE into power systems, as their electricity consumption can be adjusted to follow wind and solar PV power generation, where hydrogen becomes a medium of storage for renewable electricity.

Thus, electrolysers offer a flexible load and can also provide grid balancing services (upwards and downwards frequency regulation). The hydrogen produced can be further used in the industrial and transport sectors and as a fuel, or it can be stored and then converted back into electricity.

Moreover, stored hydrogen may enable the efficient distribution of energy across regions, facilitating VRE consumption in areas where VRE generation is difficult or direct electrification of an end-use energy application.

Providing long-term energy storage

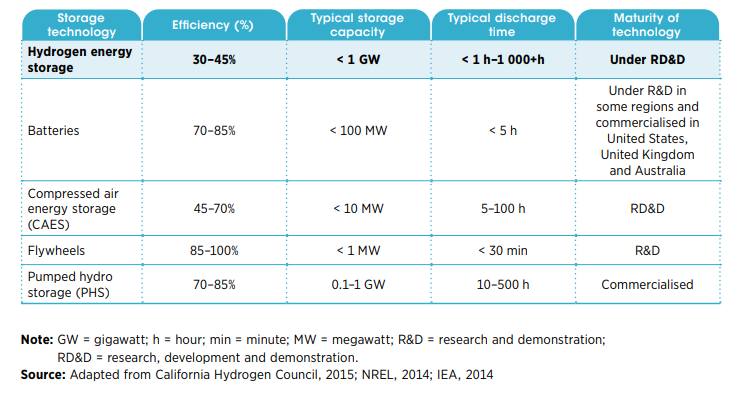

While intraday imbalances caused by VRE generation might be better managed with batteries in economic terms, seasonal variations need longterm storage solutions such as P2H₂ (Eichman and Flores-Espino, 2016). Hydrogen can serve as a long-term storage medium, with the capability of storing energy for several months. Table 2 below provides a comparison of various energy storage technologies and their storage capability.

Long-term storage options can help countries with significant seasonal differences between power demand and renewable power generation to integrate more renewable power into the grid. For example, Germany’s energy demand is 30% higher in winter than in summer. However, renewable energy sources generate around 50% less power in winter than in summer (Hydrogen Council, 2017a). P2H₂ can therefore potentially assist in shifting the supply of renewable energy from seasons with low demand to seasons with high demand.

Currently, storing power in the form of hydrogen is not financially viable. Given that a main advantage of VRE-based hydrogen is that it reduces carbon dioxide (CO₂) emissions, policy measures that account for the cost of CO₂ emissions would improve the economic case for hydrogen storage and its subsequent use for power generation. The economics are expected to improve due to technological development.

For example, the Hydrogen Council expects the cost of power storage in the form of hydrogen to fall to EUR 140 per megawatt hour (MWh) by 2030, which is lower than the projected cost for pumped hydro storage (about EUR 400 per MWh) (Hydrogen Council, 2017a).

Comparison of various energy storage technologies and their storage capability

Providing grid balancing services

Frequent fluctuations in power generation from variable sources call for rapid-response balancing options. The electrolyser systems used to produce hydrogen can be cycled up and down rapidly as a flexible load, providing grid services such as frequency regulation. The performance of alkaline and PEM electrolyser technologies differs when used to provide specific grid services. In general, alkaline electrolysers offer less flexibility as compared to PEM electrolysers, as shown in Table 3 below. Alkaline electrolysers are unlikely to offer grid services with an activation time of less than 30 seconds (Tractebel, ENGIE and Hinicio, 2017).

Supporting sector coupling strategies

Some of the applications of hydrogen sector coupling strategies are listed below.

• As feedstock: Hydrogen can be used as feedstock in the chemical industry. It is a key input to the production of ammonia, synthetic fuels and various types of fertiliser. It can also be used in the methanation process to produce methane from CO₂. Hydrogen is also used to produce synthetic liquid fuels from biomass, which increases the efficiency of biomass utilisation significantly. Hydrogen can also be used to replace fossil fuels and act as a reducing agent in heavy industries such as steel. In Sweden, for instance, the HYBRIT project aims to replace coking coal with hydrogen in the orebased steelmaking process.

• As fuel: Hydrogen can be directly used as a fuel in the transport sector or to provide power using fuel cells. For example, Europe hosts 95 hydrogen stations where a fuel cell can be refuelled in three minutes for a range of 500–800 kilometres (H₂ live, 2019). Another way to use hydrogen as a fuel is to blend it with natural gas in the existing natural gas pipelines. Standards suggest blending up to 10% hydrogen (by volume), with a potential to increase it to 20% (Hydrogen Strategy Group, 2018) (NREL, 2015) (IRENA, 2018a). However, the appropriate blend may vary significantly between pipeline network systems and natural gas compositions and must therefore be assessed on a case-bycase basis (NREL, 2013; ARENA, 2018). The current limit on hydrogen in gas turbines and engines is 1–2%, which can be increased to 10–15% with minor retrofitting (Maroufmashat and Fowler, 2017).

Micro-grids and fuel cell applications

Due to their modularity, fuel cells typically are employed in decentralised applications, offering electricity grid support and black start capability for micro-grids (Steinberger-Wilckens et al., 2017; Gardiner, 2014). In Japan, residential fuel cell systems are deployed to provide consumer grid independence. The government of Japan aims to install 1.4 million residential co-generation fuel cell systems by 2020, and 5.3 million by 2030.

Currently, more than 220 000 residential fuel cells systems are installed in Japan (Bloomberg New Energy Finance, 2017; FCHEA, 2019).

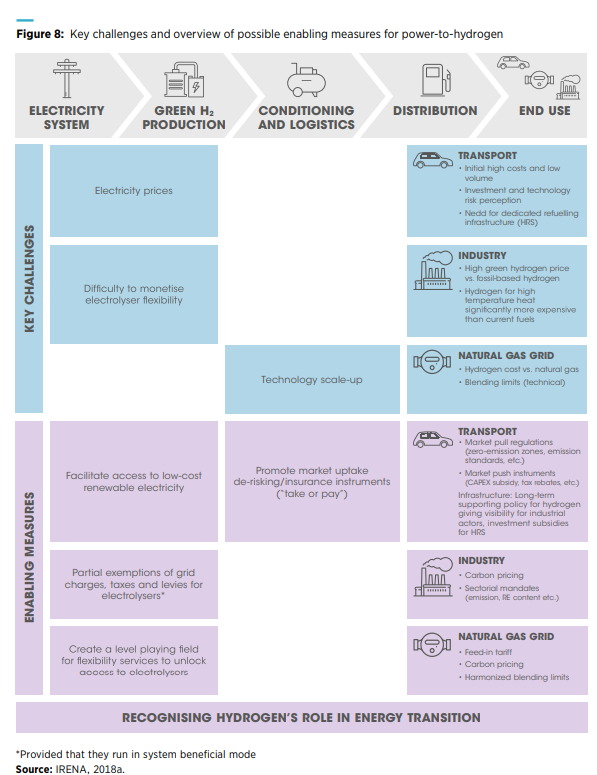

KEY CHALLENGES AND OVERVIEW OF POSSIBLE ENABLING MEASURES FOR POWER - TO HYDROGEN

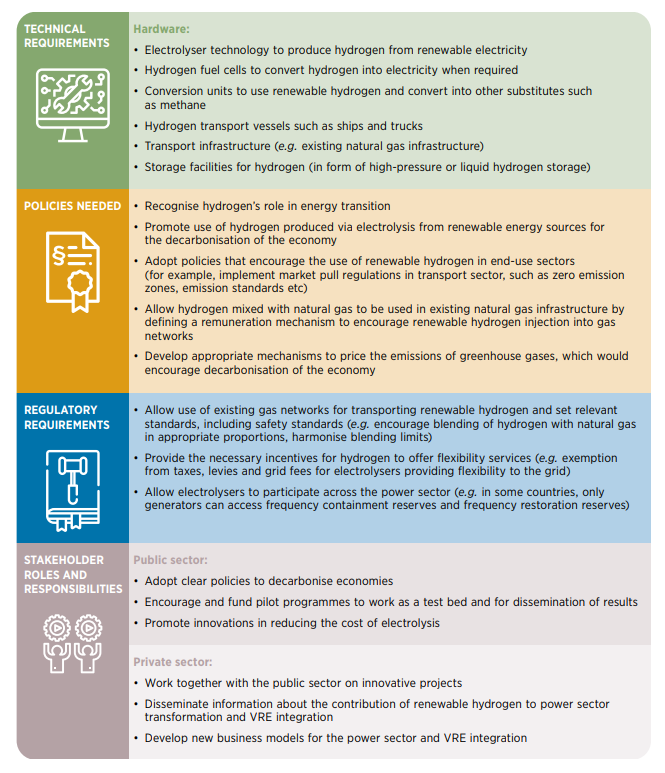

IMPLEMENTATION REQUIREMENTS : CHECKLIST

To see more :

- https://www.irena.org/energytransition/Power-Sector-Transformation/Hydrogen-from-Renewable-Power

- https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Sep/IRENA_Power-to-Hydrogen_Innovation_2019.pdf

- https://tethys-engineering.pnnl.gov/sites/default/files/publications/oes-annual-report-2020.pdf

- https://www.mdpi.com/1996-1073/14/20/6604/htm

- https://testahemsidaz2.files.wordpress.com/2017/03/oes-international-vision.pdf

- https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Sep/IRENA_Power-to-Hydrogen_Innovation_2019.pdf